Ways You Can Improve Asset Maintenance Procedure

We must strike a balance between asset productivity, purchasing, and maintenance costs. We must go further into the three notions to fully comprehend them. Assets must be created to be affordable and free of flaws; we rely on reliability, availability, and maintainability analyses for this.

1. Availability

What fraction of time may an asset be used before being shut down for maintenance or degradation? This data indicates that you must calculate your device’s availability to determine if it is critical to the success of your business and ensure its continued operation.

Calculations of asset availability

To ensure that your calculations are correct, make sure your formula contains two elements: total operating time and total downtime. Let us break down these two components. When we talk about working time, we mean the period when the appliance is doing its job, whereas downtime is when the item is not Operating.

The formulas to be used are as follows: availability=runtime (runtime +downtime)

There are two sorts of availability: instantaneous and delayed.

The average availability of uptime.

Consistent State availability.

Inherent accessibility.

We obtained availability.

Availability of operations.

This is one of several forms of asset availability, and you must understand how to compute each asset correctly.

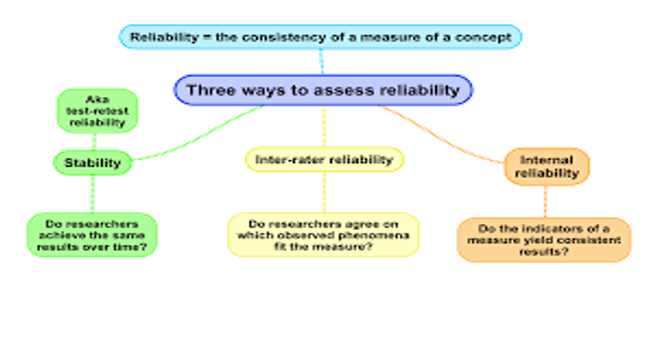

2. Reliability

A dependable asset performs predictably and consistently. It complies with all legal requirements, satisfies the business’s expectations, and meets stakeholders’ objectives. The Weibull distribution or a lognormal function can calculate equipment dependability. MTBL refers to the average time between production losses, and MPL is the number of tons lost/number of production losses.

How to improve asset dependability

MRO storeroom procedures guarantee that all material management processes are followed. Determine your spending strategy. If the storeroom is not built correctly, half of the cloth will be obsolete. Another issue is that outdated repair parts are frequently left lying in the closets.

1. It helps in specifying and prioritising the work

When you deal with assets or any other form of business best practice perspective needs to be at the top at all times, but many firms usually depend on unplanned work which is not very ideal in any industry. The moment you take time to plan a strategy on how you will deal with a particular situation will make the execution simpler. The first thing you are required to do is to identify the issue and how bad it is to plan on how you will work on it with the most minimal time possible for this to happen; the CMMS has to approve your strategy.

3. Maintainability

Maintainability is the ease, accuracy, and safety with which maintenance chores are carried out after a problem is detected. To determine maintainability, you must estimate the likelihood of the equipment reimbursing for routine aftercare. It might also apply in other sectors, such as software, where you would use simplicity to patch broken software.

Why is maintainability important?

The essential part of industrial maintenance repairs. Average repair time is the amount of time required to complete one-half of the repairs. The repair time limit is the time needed for all repairs to be conducted simultaneously and must be done within a reasonable maximum repair time.

1. Heightens organisational abilities

When your team knows the importance of maintainability, they will be able to deal with it efficiently. People responsible for repairing and maintaining equipment have different abilities and expertise. One person may know how to manage a situation while another, especially if they are inexperienced, will not.

2. Acquire the same appliances as the ones you are operating

To save time on equipment maintenance, buy identical items as airlines do. This will familiarise your personnel with various devices, making it easier to fix appliances in the field.

3. Emphasis on every asset

You must concentrate entirely on the item that has to be repaired. When this happens, your maintenance crew will not worry about not understanding how to fix a particular thing. Use software or an app to view the data from anywhere to make the repair process more accessible.

Since we have understood everything about reliability, maintainability and availability now we are going to discuss how we can improve the asset maintenance process ;

1. Issue training services to workers

Your workers are the ones who will be dealing with the assets and appliances, and they need to know how to handle every device accordingly; this is why software training is required. When your workers know how to deal with every device, fixing them will be easier.

2. Utilise preventive sustenance

To deal with preventive maintenance you should place your resources under a programme to deal with this issue, such as CMMS. This measure ensures your worker notices any fault in a specific appliance and schedules it for repair. It also increases fault tolerance, so you will see problems before they escalate.

3. Set asset priority

The moment you detect an issue in a particular appliance, you will be able to know if it needs to be repaired immediately or not. With the help of the CMMS software, you will be able to prioritize every asset and appliance. The reason why prioritizing is fundamental is that it helps increase productivity and makes sure the appliance has been dealt with on time.

You can know when to deal with the problem by looking at the asset and know-how used and whether it is used daily or just once. When you know this, you will focus on the needed investments and leave the others for later.

4. Use automated software

The moment you have decided it is time to improve your assets procedure, you should start doing away with manual work and start working with technology. Automated software is essential because it will help you deal with multiple errors that are prone to occur. The software also makes sure that your work is always organised. Also, whenever something urgent needs to be attended to, your workers will be informed.

Conclusion

Reliability, accountability, and maintainability are critical in many sectors, including asset management, and we have seen how to calculate each one and what it implies.